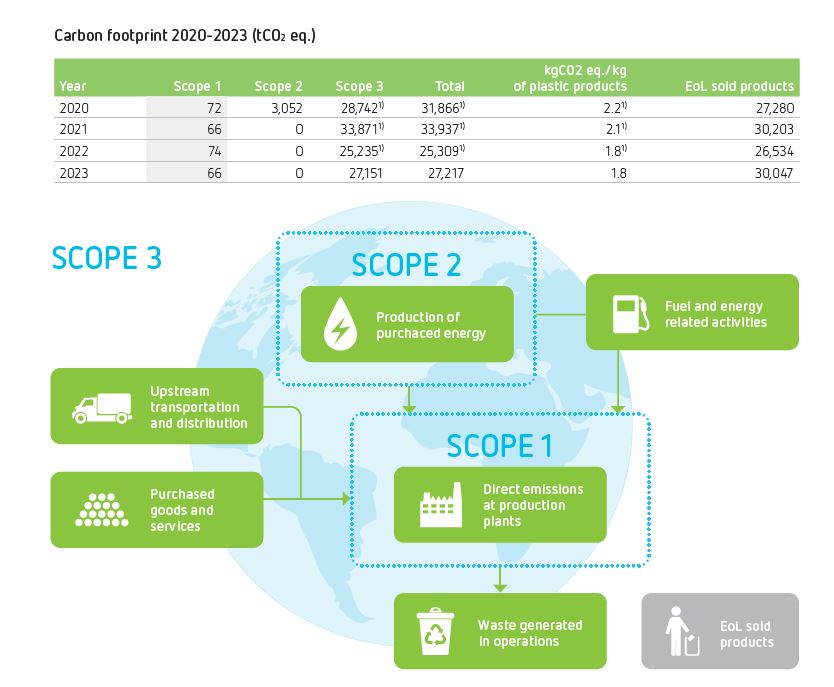

Carbon footprint

Reducing greenhouse gas (GHG) emissions and sourcing more and more of raw materials from renewable and recycled materials are at the core of our strategy and sustainability vision.

We have calculated carbon footprint of our operations and value chain, carbon footprint of some of our products and simulated our road map towards carbon neutrality, taking into account Scope 1, 2 and 3 emissions.

Orthex is committed to reducing its greenhouse gas emissions and aims towards carbon neutrality in its production by 2030.

Carbon footprint of our operations and value chain

We have calculated the carbon footprint of our operations and value chain. In addition to direct greenhouse gas emissions from our operations (Scope 1) and the production of purchased energy (Scope 2), we included the following indirect emissions (Scope 3) in our calculation: purchased goods and services; fuel and energy-related activities; upstream transportation and distribution; waste generated in operations; and end-of-life of sold products.

Most of our greenhouse gas emissions originate from purchased goods and services, such as raw material extraction, and the end-of-life of sold products, such as the incineration of products for energy. The latter is excluded from our 2030 carbon neutrality target. This is because of our limited ability to influence consumer behaviour – whether they recycle or discard our products after use – but also because it is difficult to evaluate how the recycling of plastic develops.

As our products will be in use for decades, it is likely that by the time they reach their end-of-life stage, most plastic will be fully recycled. This, and future chemical recycling, will significantly reduce the greenhouse gas emissions from the end-of-life stage of plastic products.

Increasing the share of renewable and recycled raw materials in our production will have the biggest impact on reducing our greenhouse gas emissions, and our target is to increase that share to 80% by 2030.

Carbon footprint of our products

At Orthex, we have also conducted a study to analyse the carbon footprint of products. The study was prepared in accordance with the PAS 2050 standard, a widely used specification that provides a method for assessing the lifecycle greenhouse gas (GHG) emissions of goods and services, and result were verified by a third party independent expert (Gaia Consulting Oy).

The environmental performance of different products was evaluated using lifecycle assessment methodology. Lifecycle assessment (LCA) is the guide to estimate carbon footprint of any product based on LCA-defined stages that are consecutive and interlinked. The LCA stages are raw material extraction, manufacturing, distribution, usage, and final disposal. Calculation was done for a comparative purpose where some of the stages are excluded. The reason for exclusion is that some of the stages contribute with exactly the same amount of emission, and hence does not impact the comparison. Excluded stages are raw material packaging, labelling, packaging, distribution, and the usage stage.

Based on the calculation of emissions from the SmartStore food storage containers*, the carbon footprint of the container made from bio-based plastic from sugarcane is more than 80% reduced compared to containers made from fossil-based plastic.

*The raw material data for sugar cane PE is based on the supplier’s verified calculations.

The carbon footprint of the bio-based GastroMax kitchen utensils** made from bio-based polyamide based on castor bean oil is more than 50% reduced compared to utensils made from fossil-based PA.

** The results are preliminary and based on test run production.

The carbon footprint of the SmartStore 15 box*** made from recycled material (post-consumer plastic waste) is up to 60% reduced compared to the one made from fossil-based plastic.

*** The study uses secondary data for the raw material of the SmartStore Recycled box. Primary data was not available for calculations.

The raw material has the biggest impact on the carbon footprint of the products. It is therefore increasingly important to use more renewable and recycled materials in the production to reduce the carbon footprint of products. This is a key goal in our strategy, and we aim to continuously increase the use of these raw materials in the production. It is very important for companies and consumers to recycle all the plastic they use, since it can be re-used many times as raw material for new products. Read more about recycling of our products and packaging materials.

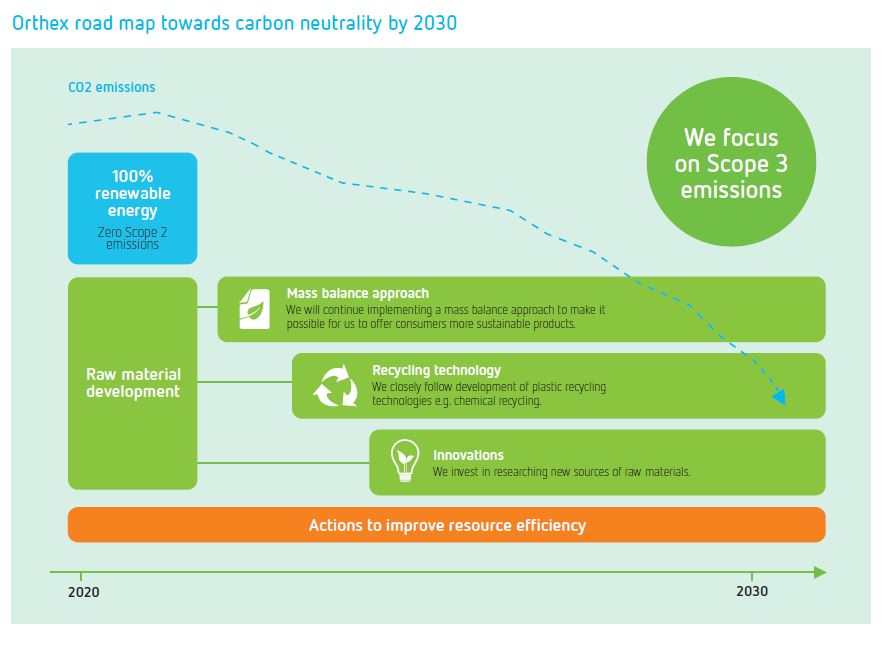

Road map towards carbon neutrality by 2030

We have set an ambitious target and are aiming towards carbon neutrality in our production by 2030. In 2022, we simulated our road map towards carbon neutrality, taking into account Scope 1, 2 and 3 emissions. In 2021, we took a significant step and replaced fossil-based electricity with renewable electricity in all our factories. This action enabled us to reduce our Scope 2 emissions to zero.

As almost all our remaining emissions originate from the raw materials (Scope 3), we focus our efforts on increasing the share of renewable and recycled raw materials in our production. Key drivers enabling us to move towards our goal are: further adoption of the mass balance approach, innovations, new sources of raw materials, and development of plastic recycling technology.

In 2022, Science-Based Targets initiative (SBTi) approved Orthex’s near term science-based emissions reduction target, which means that our climate targets are aligned with the target to keep global warming below 1.5°C in accordance with the Paris Agreement.

Storage

Storage  Kitchen

Kitchen  Home & Yard

Home & Yard  Plant care

Plant care  Renewable and recycled

Renewable and recycled